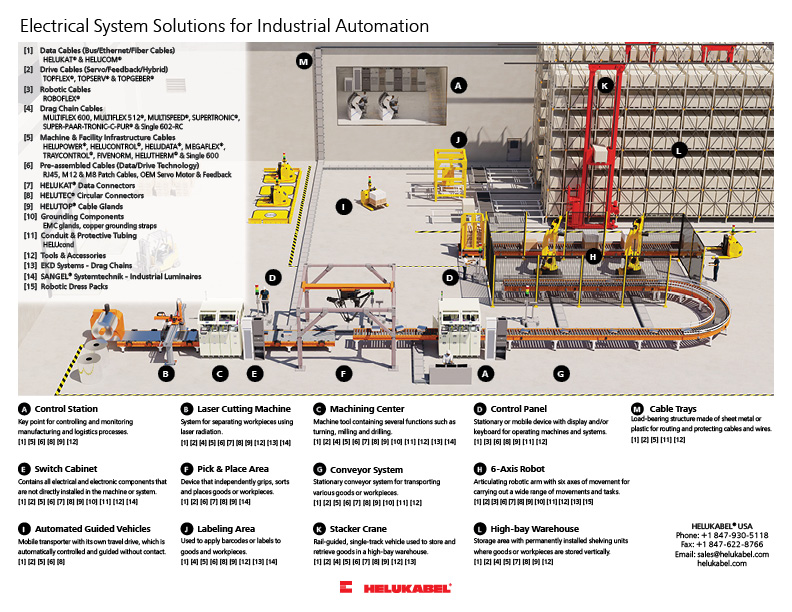

Factory Floor Applications

Whether it is controlling machines such as robots or conveyors, or sensor systems regulating temperatures and monitoring production metrics, see how and why electrical systems play a vital role in automated applications across the factory floor.

Explore how our solutions empower industries to optimize production efficiency, enhance safety protocols, and navigate the complexities of the digital factory landscape with unparalleled expertise.

Factory Applications

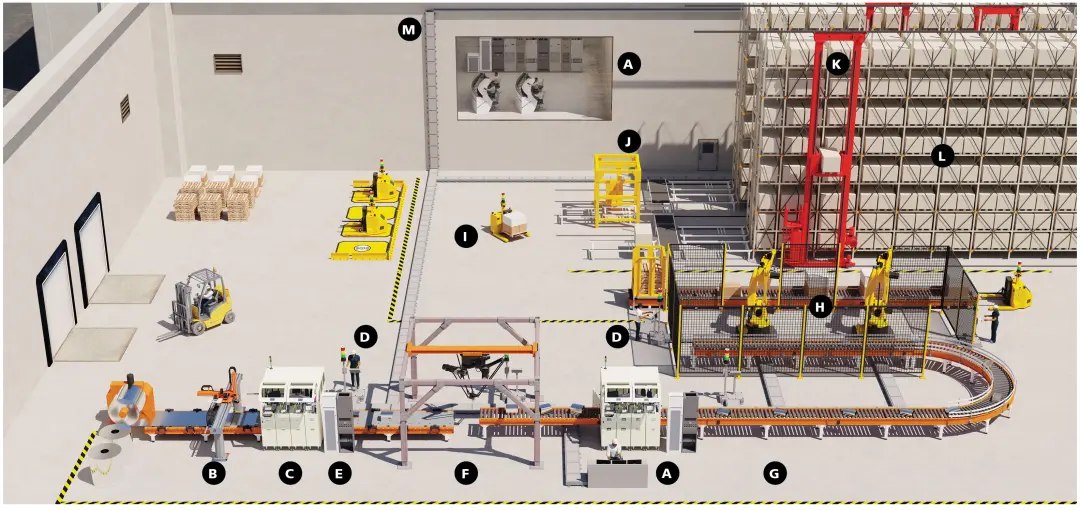

| A - Control Station Key point for controlling and monitoring manufacturing and logistics processes. [1] [5] [6] [8] [9] [12] | B - Laser Cutting Machine System for separating workpieces using laser radiation. [1] [2] [4] [5] [6] [7] [8] [9] [12] [13] [14] | C - Machining Center Machine tool containing several functions such as turning, milling and drilling. [1] [2] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] | D - Control Panel Stationary or mobile device with display and/or keyboard for operating machines and systems. [1] [3] [6] [8] [9] [11] [12] |

| E - Switch Cabinet Contains all electrical and electronic components that are not directly installed in the machine or system. [1] [2] [5] [6] [7] [8] [9] [10] [11] [12] [14] | F - Pick & Place Area Device that independently grips, sorts and places goods or workpieces. [1] [2] [4] [6] [7] [8] [9] [13] [14] | G - Conveyor System Stationary conveyor system for transporting various goods or workpieces. [1] [2] [5] [6] [7] [8] [9] [10] [11] [12] | H - 6-Axis Robot Articulating robotic arm with six axes of movement for carrying out a wide range of movements and tasks. [1] [2] [3] [4] [6] [7] [8] [9] [10] [11] [12] [13] [15] |

| I - Automated Guided Vehicles Mobile transporter with its own travel drive, which is automatically controlled and guided without contact. [1] [2] [5] [6] [8] | J - Labeling Area Used to apply barcodes or labels to goods and workpieces. [1] [4] [5] [6] [8] [9] [12] [13] [14] | K - Stacker Crane Rail-guided, single-track vehicle used to store and retrieve goods in a high-bay warehouse. [1] [2] [4] [5] [6] [7] [8] [9] [12] [13] | L - High-bay Warehouse Storage area with permanently installed shelving units where goods or workpieces are stored vertically. [1] [2] [4] [5] [7] [8] [9] [12] [13] |

| M - Cable Trays Load-bearing structure made of sheet metal or plastic for routing and protecting cables and wires. [1] [2] [5] [11] [12] |

HELUKABEL Solutions

[1] Data Cables (Bus/Ethernet/Fiber Cables)

| [2] Drive Cables (Servo/Feedback/Hybrid)

| [3] Robotic Cables

|

[4] Drag Chain Cables

| [5] Machine & Facility Infrastructure Cables

| [6] Pre-assembled Cables (Data/Drive Technology)

|

| [7] HELUKAT® Data Connectors | [8] HELUTEC® Circular Connectors | [9] HELUTOP® Cable Glands |

[10] Grounding Components

| [11] Conduit & Protective Tubing

| [12] Tools & Accessories |

| [13] Drag Chains | [14] Industrial Luminaires | [15] Robotic Dress Packs |

The product families listed above are a consolidated overview and not our comprehensive portfolio of available solutions. For more information on our electrical system solutions for robotics, please contact us.