Control cables and connection cables have two or more conductors and are suitable for many applications. These types of cables are used in many sectors, including industrial mechanical engineering and plant construction, drive and automation technology, control cabinet construction, and robotics. They are also found in electronic household appliances and tools, as well as in the transportation, infrastructure, and energy sectors.

What Is a Connection Cable?

They are responsible for transmitting electrical power in machines, facilities, and appliances. They are used to supply power to buildings and to distribute energy in power plants and transformer stations. Connection cables are also commonly referred to as power cables, electric cables, supply cables, or energy cables.

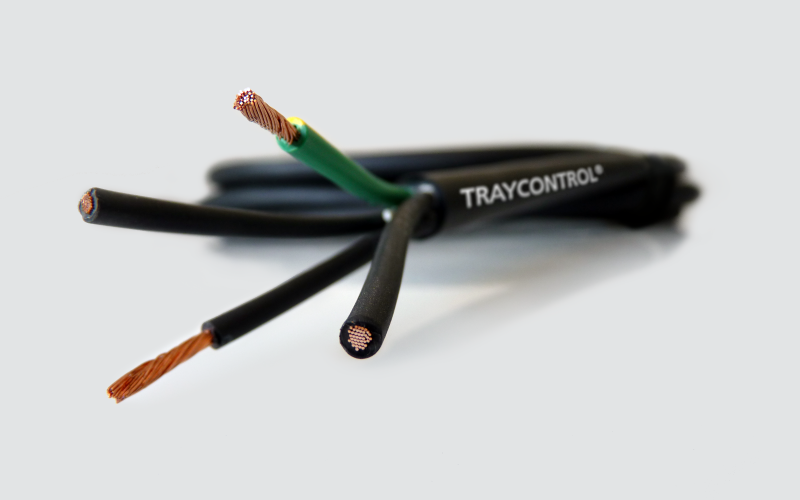

They typically consist of 2 to 5 color-coded conductors, and in most cases, each conductor has a cross section of AWG14 (2.5mm2) or larger. Usually PUR and PVC are also the most common jacket materials.

What Is a Control Cable?

Control cables transmit signals within a control circuit that governs different system components. They are used in both the internal and external wiring for components ranging from machines and facilities to sensors and actuators. Control signals instruct the receiver of the signal to perform a specific action.

Control cables are available with anywhere from 2 to 100 color-coded or numbered conductors. In most cases, each conductor has a cross section ranging from AWG20 to AWG14 (0.5 and 2.5mm2), and the jacket is typically made of PVC or PUR.

What Kinds of Control and Connection Cables Are There?

Some of the most common challenges faced by control and connection cables are dynamic movements, tensile loads, bending, and torsion, for instance when used in drag chains or on industrial robots. The cables must therefore be both flexible and resilient to oils, chemicals, weather, and UV radiation. In many applications, shielded control and connection cables are required to avoid disruptions related to electromagnetic compatibility (EMC).

Due to the wide range of applications and requirements, many different variations of control and connection cables are available with different numbers of conductors and nominal cross sections.

View Our Control & Connection Cable Portfolio

In addition to an extensive portfolio of reliable, high-quality standard solutions, HELUKABEL also manufactures custom control and connection cables according to the customer’s needs. This is how we reliably and efficiently support our customers in realizing even the most complex and extraordinary projects.

Visit our custom cable manufacturing page to end us your individual request and our experts will contact you.

You can find all our catalogs, flyers, and brochures in our Digital Bookshelf.