Tailor-Made Connection Solutions for Corrugation Machines

When producing complex production systems for corrugated board, BHS Corrugated places great emphasis on automation and modularity. Reliable connection solutions for drive systems, as well as control and switch cabinet systems, are permanent fixtures. With a comprehensive range of products, global availability, and strong technical expertise, HELUKABEL supports the mechanical and systems engineers at BHS Corrugated in realizing their projects on a global scale.

Whether shipping cartons, packaging solutions, or displays, corrugated board has become inseparable from modern logistics and global consumerism. What seems simple at first glance is, in reality, a complex, high-tech product—lightweight, stable, recyclable, and still highly customizable. To keep pace with steadily increasing demand, corrugated board manufacturers require the most advanced machine and system technology available.

BHS Corrugated Maschinen- und Anlagenbau GmbH understands this well. The company’s history dates back to 1717, when an ironworks was founded in the Bavarian town of Weiherhammer. BHS Corrugated added corrugators to its portfolio in 1960 and has since evolved into a global solutions leader for the corrugated board industry. Today, the company employs more than 3,500 people in 20 countries and achieved €827 million in revenue in 2024.

The BHS Corrugated portfolio includes complete corrugators, machines, systems, and Industry 4.0 solutions, as well as logistics concepts and printing technology. These large-scale production systems, used in the manufacture of corrugated board, can be up to 200 meters long. For this reason, they are designed with a modular construction. Individual system components are assembled at the company’s various international locations and then transported to customer sites by truck or sea freight. Final assembly and commissioning of the complete corrugator line then take place on site.

Technical diversity and global requirements

The gigantic corrugated board machines from BHS Corrugated can be up to 200 metres long. (Image source: BHS Corrugated)

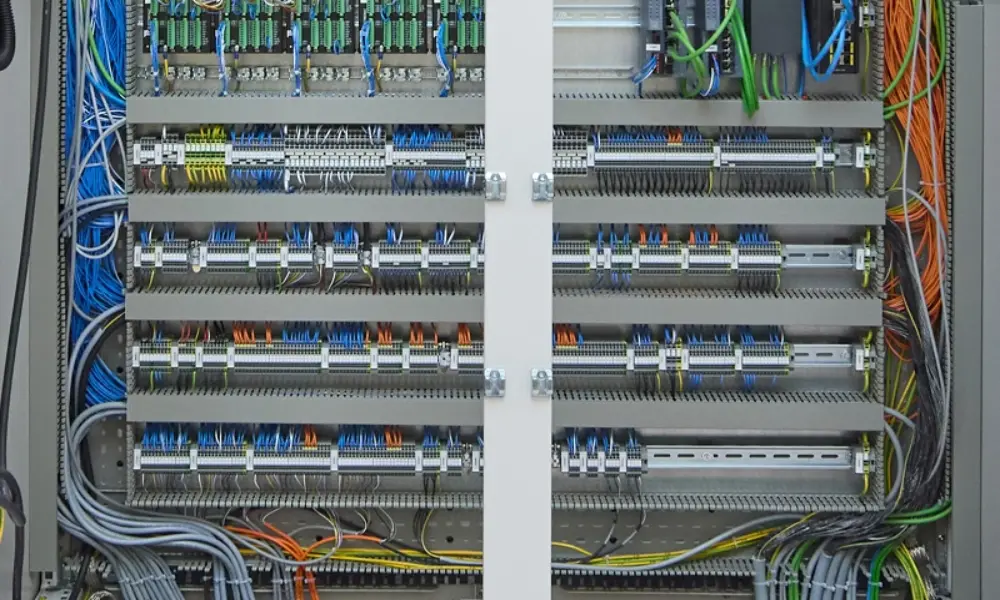

Electrical connection technology is an indispensable component of highly automated machinery. In drive and control technology, as well as in control cabinet construction, many different types of cables and wires are used. As a systems supplier, HELUKABEL has been a trusted partner for BHS Corrugated for decades, supported by a product portfolio that reliably covers a wide range of requirements across all applications.

They supply control and connection cables such as the versatile JZ-500, data cables such as the flexible TRONIC-CY, TOPSERV servo cables, and TOPFLEX motor cables. For control cabinet wiring, single conductors from the FIVENORM product range are commonly used. These conductors are certified to five different international standards and are therefore suitable for global use.

“This is an important criterion for us, as we export many of our corrugators to the USA, China, and other international markets,” explains Markus Schrödl, Electrical Engineering Specialist at BHS Corrugated. “Global approvals are often strictly required for the components that we use.”

Even for automated processing and printing using a Komax machine, as is the case at BHS Corrugated, the FIVENORM single conductors are a perfect match.

Ready for installation at workstations

BHS Corrugated sources the cables required for installing individual system modules in Weiherhammer primarily from a nearby prefabrication partner. These cables are prepared to the required lengths, fitted with the appropriate connectors, and pre-sorted into specially designed installation carts that can be placed directly at each station along the production line. “Our employees only need to take one cable at a time and install it in the correct place in the machine. This saves a lot of time and effort,” says Schrödl. Other custom products required for final installation at the customer’s site are delivered together with the machine.

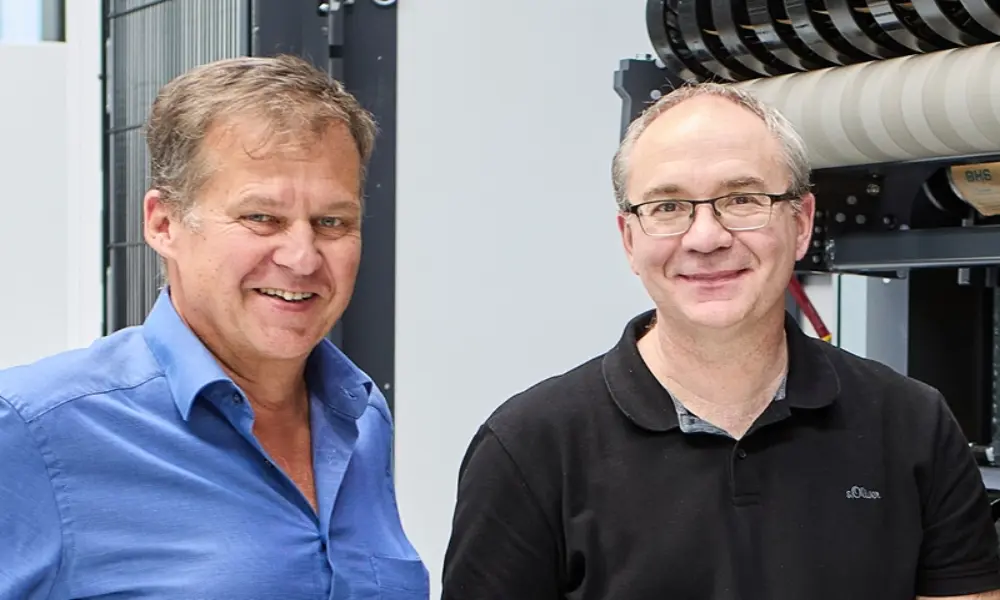

For the experts at BHS Corrugated, the global availability of HELUKABEL products is another key advantage. With 76 locations worldwide, HELUKABEL ensures that replacement parts are readily available when needed. “For a supplier like BHS Corrugated, which services systems worldwide, this is a real competitive advantage,” explains Thomas Puchta, Area Sales Manager at HELUKABEL and BHS Corrugated’s primary point of contact.

Markus Schrödl also praises the friendly support and technical expertise provided by HELUKABEL. “The open and straightforward communication with the HELUKABEL sales team has truly shaped our collaboration and allowed it to continue developing,” he says. Their colleagues in the office are also easy to reach when questions arise and are always willing to provide quick and effective solutions. Clear and detailed technical documentation on the website further reinforces the confidence of BHS Corrugated’s leadership that they are in good hands with HELUKABEL.

Declared a preferred supplier

Markus Schrödl (r.), Electrical Engineering Specialist at BHS Corrugated, and Thomas Puchta, Regional Sales Manager at HELUKABEL. (Image source: HELUKABEL)

In July 2025, the systems engineers formally recognized their appreciation by naming HELUKABEL a preferred supplier to BHS Corrugated. Christian Schneider, Group COO, personally traveled to Hemmingen to deliver the news. “We are very pleased with this recognition, as it reflects the trustworthy and cooperative collaboration between BHS Corrugated and HELUKABEL,” explains Thomas Puchta.

Today, roughly 95% of all cables installed by BHS Corrugated come from HELUKABEL, and additional projects are already being planned. “Our companies share the same goal of setting standards through quality and innovation, while developing solutions together that meet future demands,” emphasizes Markus Schrödl. “For this reason, connection technology from HELUKABEL will remain a central component of our machines and systems.”

ABOUT BHS CORRUGATED

BHS corrugated Maschinen- und Anlagenbau GmbH is the leading solution provider for the corrugated board industry. With more than 3,500 employees at their headquarters in Weiherhammer, Germany, as well as in more than 20 countries across the globe, the lifecycle partner has an impressive spectrum of products and services. This includes the areas of corrugated board machines, systems, and factories, Industry 4.0, logistics, as well as single-pass inkjet digital printing. They supply customers with holistic solutions spanning development and production, installation, maintenance, and service.

Learn more at www.bhs-world.com/en

You can find this article as well as many more exciting stories in our latest issue of POWER #18.