Electrical Connection Solutions For Biogas Applications

HELUKABEL supplies advanced cable solutions for biogas facilities in the Dakotas.

As the world continues its transition to cleaner, more sustainable energy sources, the production of renewable energy projects like biogas and biomethane becomes increasingly important. These technologies help reduce reliance on fossil fuels and mitigate environmental impacts. The benefits of biogas go beyond providing a renewable energy source; they also play a significant role in waste management, recycling organic materials that would otherwise contribute to methane emissions in landfills. This shift toward greener energy solutions is part of a broader movement to combat climate change and address global warming.

These are not distant ideas — they are happening now. But while Europe leads the global biogas market, the U.S. is just beginning to scale its presence. Currently, the U.S. accounts for roughly 1/6 of global biogas capacity, lagging behind countries like Germany and China.

To enhance it’s biogas generation capacity a global bioenergy technology partner built out two state-of-the-art biogas plants in the heart of the Dakotas — and at the core of these operations is a surprisingly unsung hero: cable infrastructure. From power distribution to data transmission, HELUKABEL cables are helping energize the next

generation of renewable energy.

The customer, a leading developer of biogas and biomethane facilities with over three decades in the renewable energy space, selected HELUKABEL to support the cabling requirements of their newest U.S.-based facilities since the approvals they were used to globally didn’t comply with those in the US market, where UL sets the standard. HELUKABEL supplied a tailored mix of tray-rated control power, Industrial Ethernet cables, and VFD motor cables — each engineered to perform in the harsh and demanding environments of biogas production.

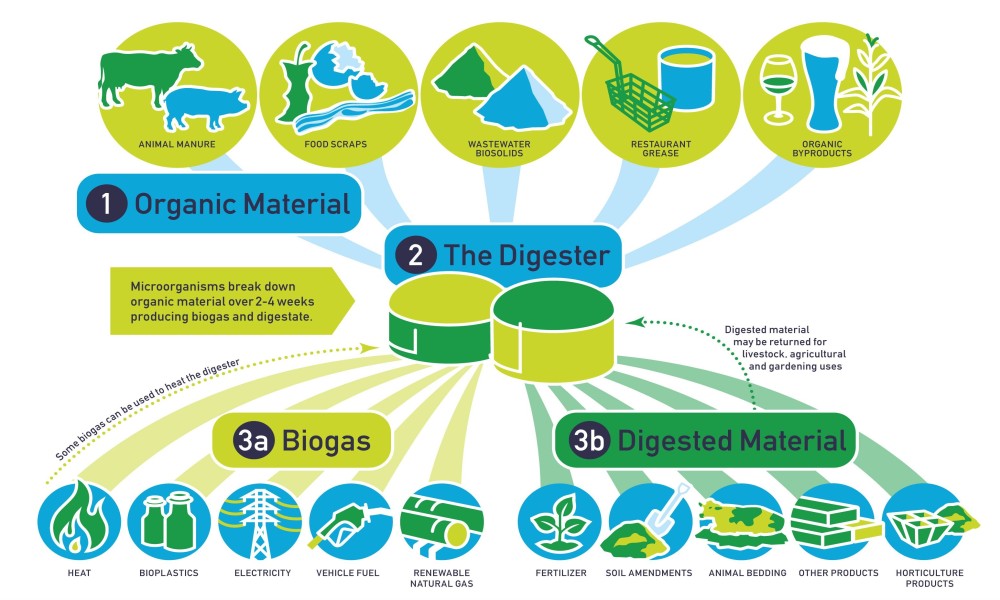

From Cows and Compost to Clean Energy

How organic waste is transformed into clean energy, soil nutrients, and sustainable byproducts through anaerobic digestion.

While industries are often cited for contributing to greenhouse gas emissions, another culprit continues to fly under the radar: biology. Livestock waste and food decomposition naturally release methane and CO2 — but on an industrial scale, the emissions become a serious environmental issue. According to The Breakthrough Institute, livestock waste contributes nearly 15 percent of global greenhouse gases. The United Nations Framework Convention on Climate Change (UNFCCC) adds that food waste is responsible for another nine percent.

Biogas facilities offer a solution by capturing these emissions and converting them into energy. Through a process called anaerobic digestion, bacteria break down organic waste in oxygen-free conditions to produce biogas, a fuel primarily composed of methane. That gas can be used to generate electricity, provide heating, or even be refined into biomethane for use as vehicle fuel. The process also yields a nutrient-rich digestate that can be reused as agricultural fertilizer.

Why Infrastructure Matters in Bioenergy

As more biogas and biomethane facilities come online in North America, the demand for durable, future-ready electrical connection technology for plant infrastructure will grow. These systems must run around the clock, often in remote or rural areas, with little room for electrical failure or downtime.

Having quality products that meet UL approvals is why this bioenergy developer turned to HELUKABEL.

Our TOPFLEX® 600 VFD cables were deployed to supply reliable power to motors and pumps throughout the anaerobic digestion system, where organic waste is converted into clean, usable fuel. These cables are designed to withstand electrical noise (EMI), harsh temperatures, and mechanical stress — all common challenges in facilities like these.

Meanwhile, HELUKAT® 600 LAN cables and HELUKAT® PROFINET Industrial Ethernet cables were installed to ensure consistent, real-time communication between programmable logic controllers (PLCs), sensors, and HMI systems throughout the plants. Proper data transfer plays a key role in helping operators monitor operations and maintain peak performance from digestion through gas cleaning and conversion.

The Road Ahead

As the U.S. ramps up efforts to decarbonize its energy systems, biogas represents a unique opportunity: a renewable energy source that is not weather-dependent like wind or solar, and that also tackles agricultural waste at its source.

HELUKABEL is proud to support the backbone of this movement — not just in words, but through real-world engineering. Our involvement in these Dakota-based projects showcases how advanced cable technology can drive reliability and efficiency where it matters most.

We look forward to supporting more customers in the renewable energy space, helping turn methane from a threat into an opportunity — one cable at a time.

Article Download

Click here to view this article in our digital download center.