Robotic Cable Protection Systems

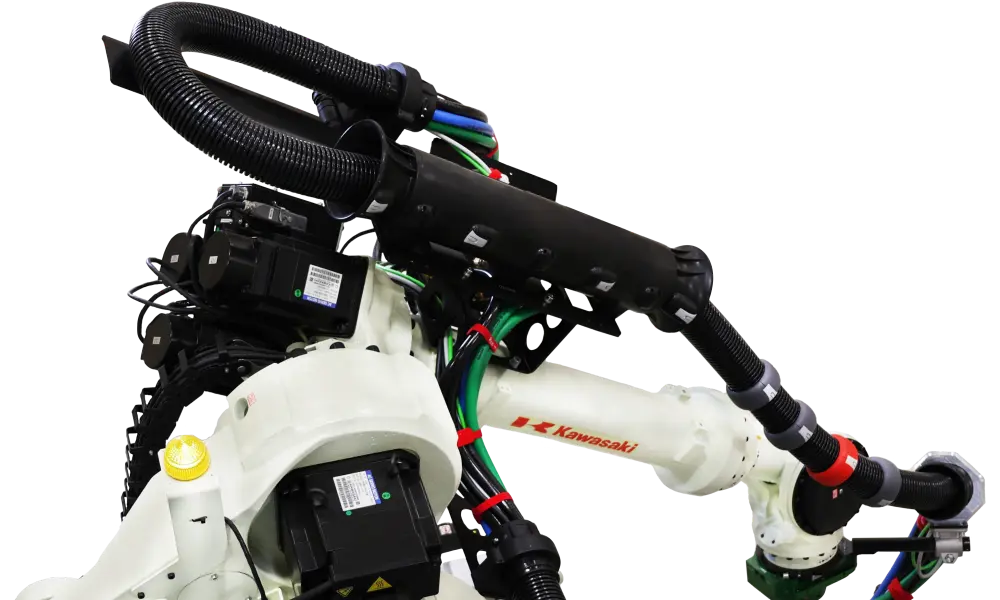

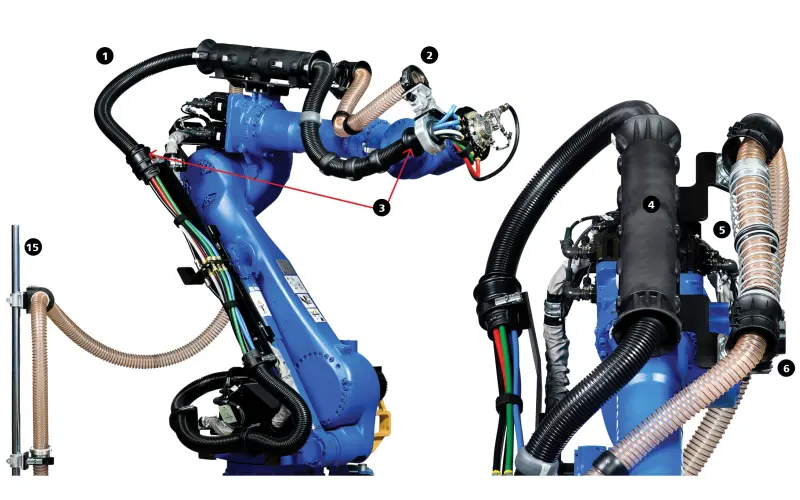

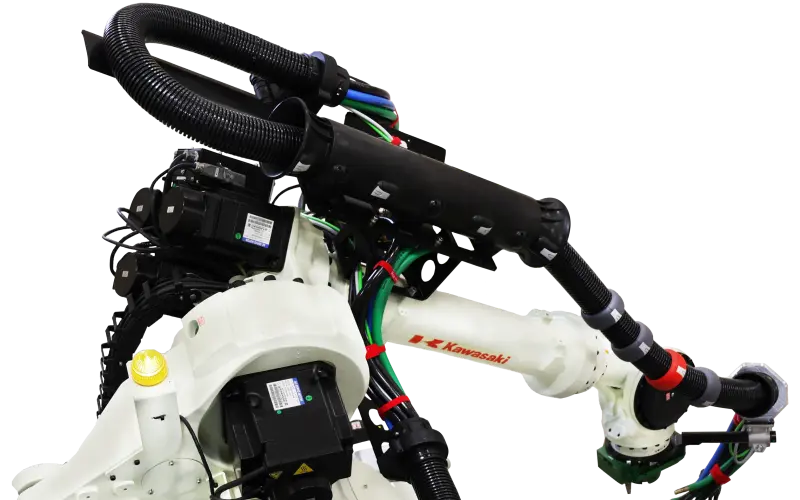

Dress packages (a.k.a. dress outs, umbilicals, utility supply systems, etc.) provide an organized way of protecting the fill package from environmental hazards, which helps reduce time spent on preventative maintenance. Any industrial robotic application where an End Of Arm Tool (EOAT) needs various power or data transmission such as servo power, welding power, water supply, Ethernet communication, etc. needs a dress pack.

Robotic dress packs are tasked with protecting, managing, securing and guiding cables and hoses over millions of work cycles. These high demands place an enormous amount of stress on every component within the system. Unfortunately, failures will occur. It’s a matter of when, not if a problem will arise. Over 85 percent of robotic downtime is attributed to fill package failures.

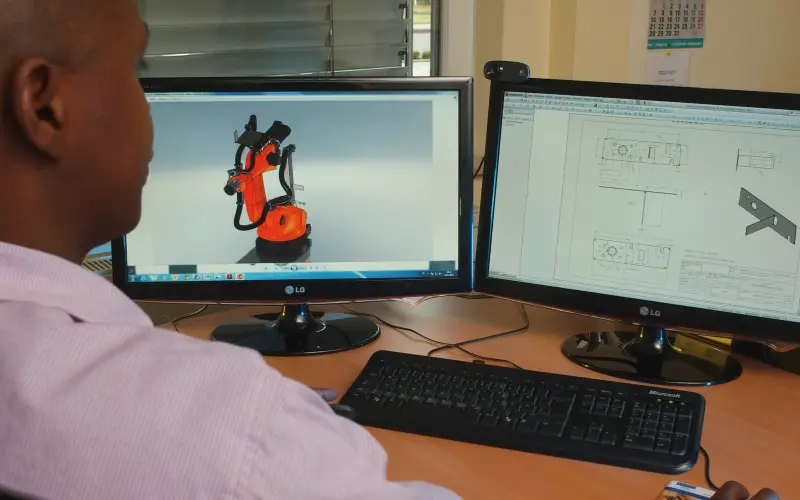

Clear drawings of the fill package and 3D drawings for how and where to mount the dress pack hardware ensure proper installation on the robot.

In order to mitigate failures in the best way possible, it is important to select solutions from an application-specific, as well as an overall system, point of view. In other words, each robot has a task to perform. Therefore, dress packs should be specifically designed around the complete work cycle of each task.

HELUKABEL's engineers work with each customer to design and build a dress pack that is unique to their application in order to ensure each robot's fill package is protected and guided properly to avoid any unwanted downtime.

Manufacturers We Can Support

|

|

We are happy to help you select the right products for your specific application and are available to answer any questions you may have.