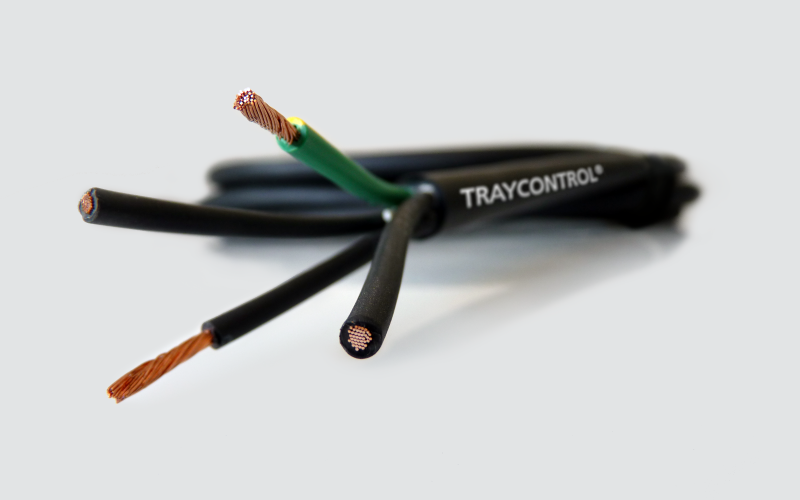

What is Flexible Tray Cable?

Tray cable (TC) is a viable alternative to traditional command and power cables (MTW, ST, SJT, SOOW, THHN, etc.) used in industrial applications. Products that are UL Listed also meet NFPA 79 requirements, which allows users to store only one cable type in their warehouse. Here are some additional reasons for when and why you should consider using flexible, tray-rated cable.

Applicable Industries

Industrial Automation, Event, Theater and Stage Engineering, Food and Beverage, Machine Building, Material Handling, New Plant/Facility Construction, Renewable Energy, Robotics, Wood, Pulp and Paper Manufacturing, and Ferrous/Non-ferrous Metal Manufacturing, among many others.

Installation

Cables that are TC rated are capable of being installed in cable trays instead of in conduit. Compared to less flexible Class B-stranded tray cable, finely-stranded (Class K) cables have a much smaller bend radius due to their increased flexibility. Therefore, installers can have tighter cable routing, and easily terminate using standard cable glands instead of using conduit, which is more labor intensive to install, costs more to inspect, and harder to move during a plant reconfiguration. Overall, this results in substantial cost savings in both materials and labor (reduced installation time). Additionally, tray cables can exit the tray and be exposed for up to six feet if they are exposed run (-ER) rated, i.e. TC-ER, PLTC-ER, ITC-ER.

Finally, tray cables are safe for use in Class 1, Division 2 hazardous locations (gases and vapors not normally present, but may appear), Class 2 control circuits, and when needed they can be directly buried or installed in sunlight due to their resistance to UV rays.

Oil Resistance

Tray cable is rated Oil Res I/II to withstand many types of oils, lubricants and fluids, and therefore suitable for the demands of the electrical requirements found in industrial applications.

Operating Temperature

New compound formulations allow tray cables to operate at 90°C in both dry and wet applications. Additionally, they also pass the UL -40°C cold bend test.

Voltage

Most tray cable is approved for 600 V applications, but tray cables that are WTTC rated are approved for 1000 V applications such as in wind turbine applications. Tray cables marked as Flexible Motor Supply are approved for 1000 V demands found in VFD drives both with and without signal pairs, i.e. flexible motor supply.

Flame Retardancy

Tray cables are self-extinguishing and flame retardant according to the UL VW-1 (UL 1581) and the CSA FT4 Vertical Flame tests.

Approvals

Tray cable’s versatility comes from the many approvals that it meets such as TC-ER (UL 1277), WTTC (UL 2277), PLTC-ER, ITC-ER, NFPA 79, MTW, CIC-TC FT-4 (C22.2 No. 230 & 239) and CSA AWM I/II A/B (C22.2 No. 210). For companies that heavily export, the CENELEC (CE) approval is required for tray cables to be used in the European Union. Having this stamp means that tray cable products conform to CE low-voltage directives.

Industrial Tray Cable Applications

| Application | UL Requirements |

| 1 Continuous-Flex, Power | UL cable marked “flexing”. UR AWM-type cable for flexing application or cable track. NFPA 79 Clause 12.9 |

| 2 Closed Cable Tray | Cable type: TC-ER, TC, MTW, THHN |

| 3 Open Cable Tray | Cable type: TC-ER |

| 4 Control Application | Cable type: CMG, CM, CMX, ITC, PLTC |

| 5 Hazardous Location | Cable suitable for use in hazardous location. Attention: Cable selection depends on the area classification |

| 6 VFD & Servo Motor | FIXED TC-ER or UR AWM cable rated for tray/conduit installation. FLEXING UL or UR AWM cable rated for continuous-flex applications). NFPA 79 Ch. 4 Article 4.4.2.8 |

| 7 Fixed, Power | Cable type: TC-ER. UR AWM cable for flexing application + conduit listed (ex. LFNC). NFPA 79 Clause 12.9 |

| 8 In-Floor Cable Tray | TC-type cable marked “Dir Bur“ (Direct Burial). TC-type cable inside raceway listed for direct burial |

| 9 Control Panel | Single conductor, AWM cable UL Style 1015 single conductor, MTW cable |

What are UL Standards 1277 & 2277?

UL 1277 - Electrical Power & Control Tray Cables

Cables must be 18 AWG and larger, and carry a maximum voltage rating of 600 V. They can be denoted as TC or TC-ER. The -ER or “exposed run” allows cable to come out of the cable tray unprotected for ≤ 6 ft. (1.8 m) if it passes crush and impact tests.

UL 2277 – Flexible Motor Supply Cable & Wind Turbine Tray Cable

Cables must be 18 AWG and larger, and carry a maximum voltage rating of 1000 V. They can be denoted as WTTC for cables being used in control power applications or Flexible Motor Supply Cable if being used as a VFD motor power cable.