Always Energized

Electric vehicle (EV) racing has been gaining traction in many parts of the world and includes such series as Formula E, MotoE World Cup and Extreme E, to name a few. The popularity of EV racing has also found its way into universities around the world including the University of Illinois Urbana-Champaign, where each year, Illini Formula Electric (IFE) designs and assembles its own open-wheel, formula-style electric race car. Members of IFE are developing an all-electric race car to compete in the annual Formula Society of Automotive Engineers (FSAE) competition. Students from various academic fields of study – Computer Science, Mechanical Engineering, Aerospace Engineering, and Electrical Engineering and many other areas – have membership in IFE and work together to fulfill the goals of designing and manufacturing the hundreds of pieces and systems that go into the final product of a high-performance formula E-style car. Each year is dedicated to the creation of a new car that meets the competition’s strict guidelines, with the first semester of the academic year focused on design and the second semester dedicated to the manufacturing of the vehicle.

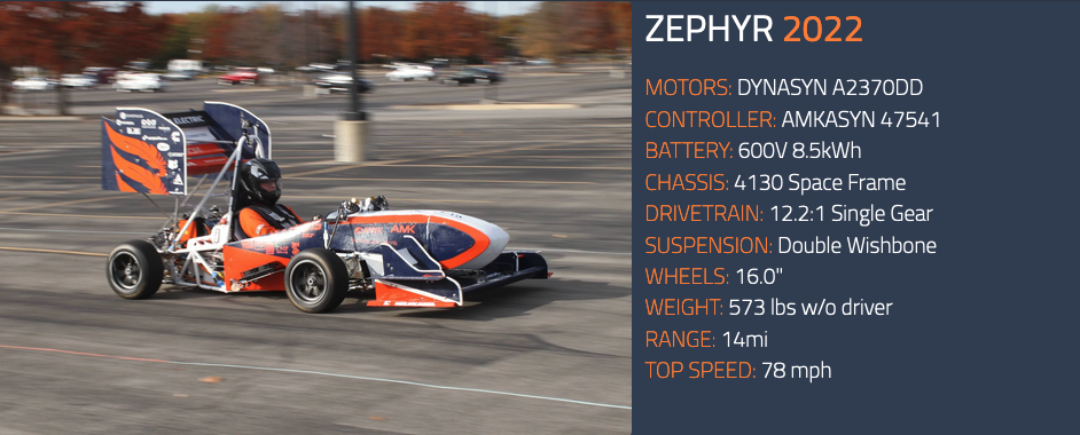

During the 2021-2022 season, IFE transitioned from a single-motor, rear-wheel drive to a quad-motor, four-wheel drive car. This required the team to overhaul the mechanical and electrical design of the car to accommodate the transition. Mechanically, the in-hub planetary gearbox was designed to transmit the motor torque to the wheels, which were located in the uprights of all four corners of the car. Since the four motors required active cooling, a new water-cooling system was designed to provide adequate temperature control. The chassis also required a design overhaul to ensure that the new electrical components such as the accumulator and inverter were mounted securely to the car.

Far from the typical roaring engines found in traditional motorsports, IFE uses electric motors to propel the car rather than fossil fuels and internal combustion. The EV market has skyrocketed within the last decade, with 400,000 EVs being sold in 2021 in the United States alone. With rising environmental concerns surrounding carbon footprints and more companies rolling out their own lines of EVs, learning the process that goes into the creation of these vehicles and the market landscape is more important than ever.

FSAE has been following the upward trend of EVs since the beginning. Having been around since 2013 this event has provided an opportunity to test the limits of EV performance for almost a decade. The competition has two main categories: dynamic and static. The dynamic events include acceleration, autocross, endurance, and skid pad. Static events are focused on the process of creating the car and include a business presentation, cost report, and design review. However, teams are only permitted to move on to the dynamic events if the car can pass multiple safety tests and examinations. Strict safety regulations are required for the electrical components of the cars due to the high voltages, high currents, and the danger of severe shocks to anyone who comes in contact with the vehicle.

All race cars entering FSAE’s electric competition must go through a very detailed inspection of the electrical systems for safety compliance. One of the most rigorous of these tests is the rain test, which puts the car under a sprinkler system for two minutes while an insulation monitoring device (IMD) is activated to check for any faults. A fault would indicate a short in the system. In order to pass these tests, high-quality electrical cables are needed to withstand the demands of performance and safety. After reviewing the competition’s electrical specifications, IFE reached out to its cable partner HELUKABEL USA to sponsor the team for the fourth consecutive year.

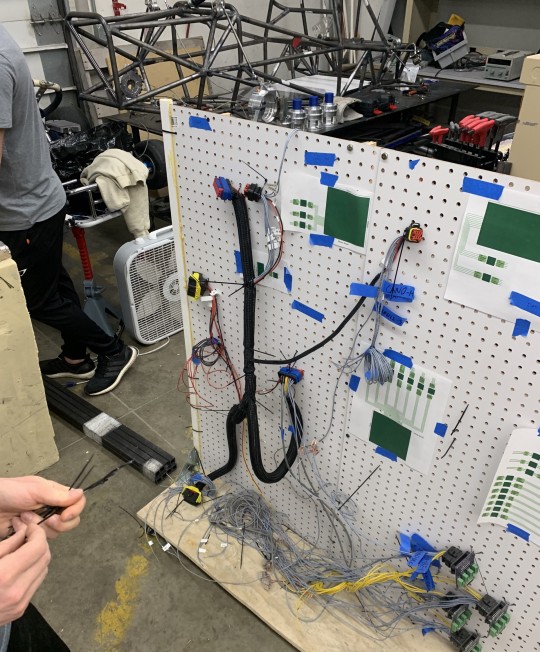

For the 2021-2022 season, HELUKABEL made a generous donation of more than 1,640 feet (500 meters) of various wire sizes, colors and types to help support IFE’s conversion to an all-wheel drive setup. The three-phase inverters received power from the accumulator using HELUKABEL’s AWG 6 HELUTHERM® 145. This single-conductor cable was extremely durable, and its flexibility made it easy to route the cable throughout the chassis to where it was needed. The high current and voltage rating ensured that the high voltage path on the car met all safety requirements. The three-phase inverters supplied alternating current to the motors via HELUKABEL’s AWG 8 Single 602-RC-CY-O. The cable was shielded to help limit interference to the car’s data signals and the high current and temperature ratings met the team’s needs exactly. HELUKABEL also supplied IFE with black, red, white, and gray AWG 18 LifY single-conductor wires for the low-voltage signals. The high flexibility of these cables, due to the extra-fine stranding, enabled the car’s electrical harness to make tight turns that would not have been possible with solid conductor wires.

The success of the Illini Formula Electric team’s car would not have been possible without the support of donations from companies like HELUKABEL USA. Due to global supply chain shortages and delays, IFE was not able to test their car in time for the competition. Despite this, IFE was still able to place 24th out of 55 teams based on their performance in static events like cost, business, and design. The lessons from the 2022 season allowed IFE to learn more about their transition to all-wheel drive (AWD), including four motor wire harnesses, motor cooling, and torque vectoring hardware and sensors.

Beyond the track and workshop, the IFE team also had 100 percent of its graduating members either get into graduate school for additional studies or receive employment to apply the skills they have acquired into practical application to shape the technology of tomorrow.IFE is excited to continue its partnership with HELUKABEL for the 2022-2023 competition season. Although the AWD conversion was tough last year, this year looks very promising for IFE. The team is currently working on updating the designs of the 2021-2022 car to increase reliability and efficiency, as it prepares for the 2023 FSAE Electric competition. The team has learned a lot during the conversion process and with the help of sponsors like HELUKABEL will continue to keep pushing the boundaries of what their CAD and ingenuity can do.

About the Car

Illini Formula Electric (IFE) is the University of Illinois Urbana-Champaign’s electric Formula SAE team. We design, build, and race electric formula cars. Starting in 2010 as Illini Hybrid Racing, the organization initially designed and competed hybrid formula vehicles. In 2013, Illini Hybrid Racing became Illini Formula Electric and designs transitioned to a fully electric vehicle. IFE is comprised of over 20 different majors, with students from over 4 different continents, speaking languages spanning a multitude of cultures. Prospective members can join as soon as their first undergraduate year or as late as their final postgraduate year. We recruit from a wide array of disciplines ranging from business and accountancy, to applied and theoretical sciences. Our alumni network is over 200 strong and reaches a wide array of industries.

For more information on the team, visit www.illiniformulaelectric.com .

ARTICLE DOWNLOAD

Click here to view this article in our digital download center.