Cable & Wire Applications in Wind Power Generation

See how cables, wires and accessories are used from the turbine to the grid.

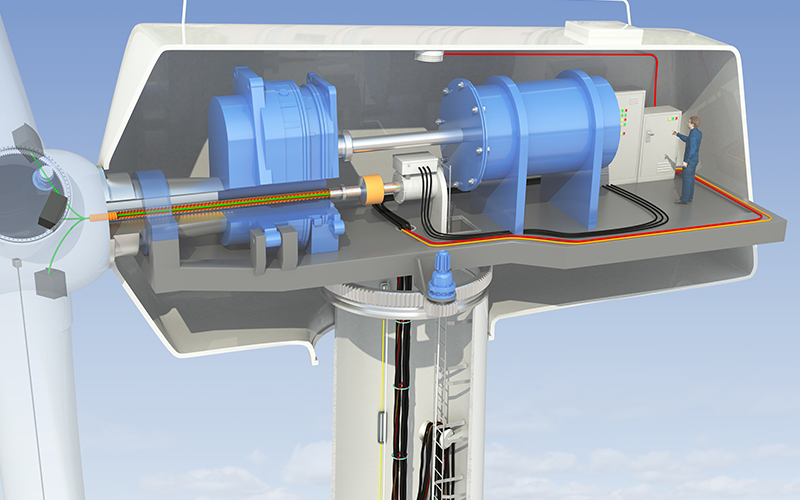

Nacelle

Oil-resistant cables for high temperatures

• Highly flexible control and bus cables for heavy mechanical loads in rough environments found in rotating components

• Hybrid cable solutions with increased current carrying capacity for the supply and control of the pitch drive (rotor blade adjustment), from the slip ring through the hollow gearbox shaft to the hub

• Torsion-resistant, fire detection cable

• Copper and fiber-optic data and communication cable

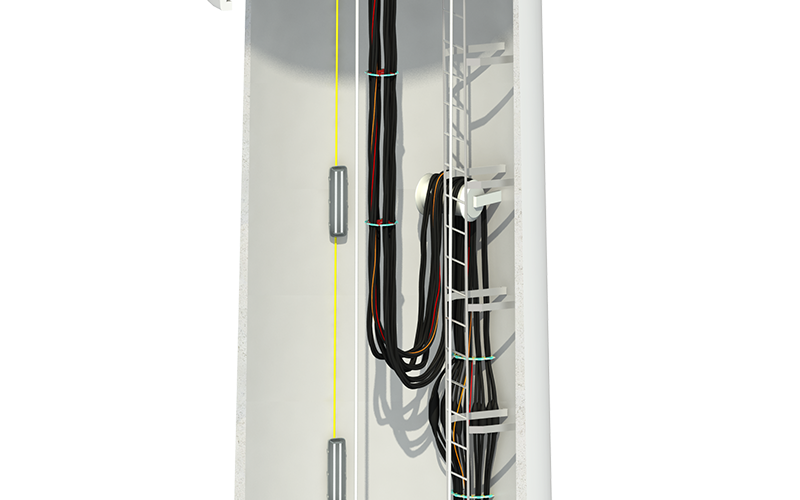

Loop

WK Series — Torsion-resistant cables

• Tested for more than 15,000 torsion cycles

• For climate zones from -40°C to +145°C

• Oil, ozone and UV-resistant

• Multiple approvals available

• Cable grips

Tower

Aluminum & copper cables

• Multi-conductor and finely stranded versions, specific alloys

• 600/1,000 V – 35 kV

• VDE, CE, UL/CSA listed

• Fastening systems from leading manufacturers

WK Lift cables

• Supply cables for lifts

• Carriage version for mid-level feed-in, optional as flat cables

• High bending and abrasion resistance

• CE & UL/CSA approvals

Extensive connectivity solutions

• CU/CU – AL/AL – AL/CU

• Available as crimp and screw fitting version

• Crimp tools: electro-hydraulic and hand-held press tools

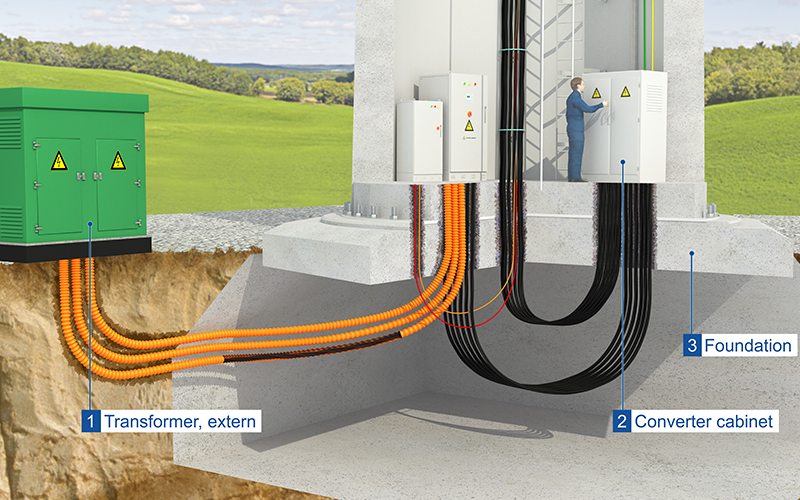

Base

Multi-conductor and finely stranded power cables

• Aluminum and copper cables

• 600/1,000 V to 35 kV for direct burial

• Conduit systems

Connection to the grid: medium-voltage cables

• Aluminum and copper cables

• All voltage levels, cross sections up to 507 kcmil (1000 mm²)

• Length and laterally watertight

• Connection & indoor termination sleeves