Cables, Wires and Accessories for Robotics

Robots are an integral part of the manufacturing industry worldwide to the extent that they are indispensable. In production, robots and cobots frequently encounter each other, working and interacting side-by-side with humans, but also performing tasks independently. The latest industrial robots move in a three-dimensional (3D) space and can therefore perform a wide variety of tasks.

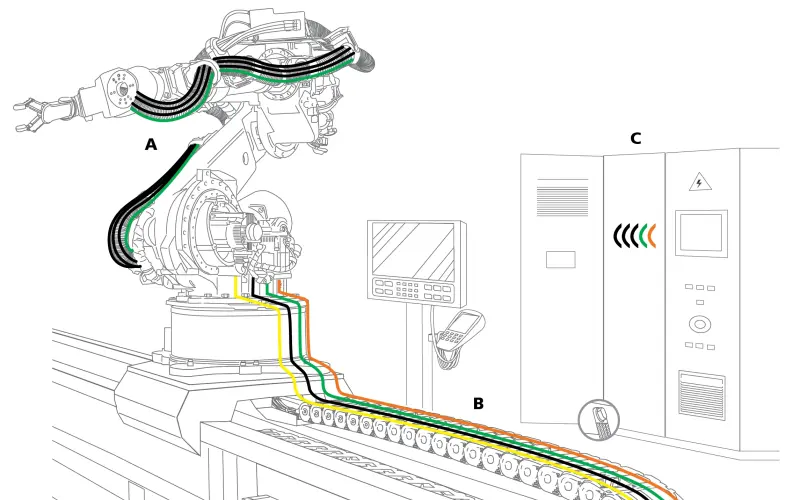

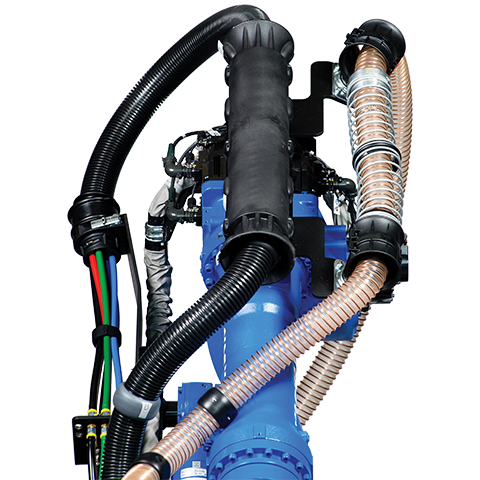

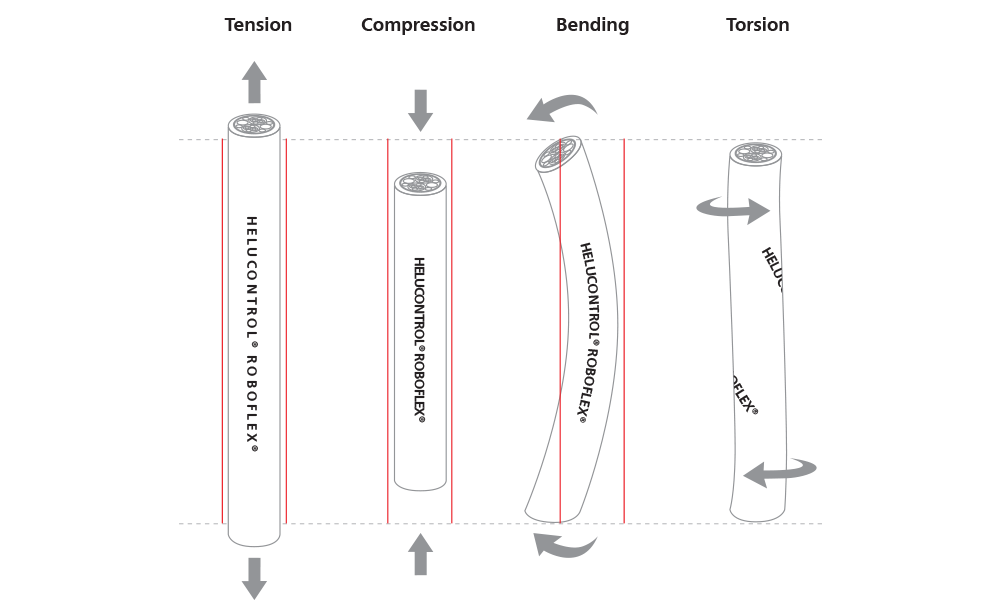

The motion sequences of a robot or a robot arm are repeated millions of times and in all directions. They offer continuous precision and consistent quality for repetitive tasks even under extreme conditions. Strict requirements are placed on robot cables due to strong acceleration and deceleration, loads from tension and 3D stress, a combined stress coming from torsion and bending. Not only should they meet these requirements, but depending on their intended use, they must also be guided in or onto the robot arm in a tight and space-saving manner in order to achieve the greatest possible freedom of movement.

The forces acting on robotic cables and wires.

HELUKABEL offers single and multi-conductor cables with different cross sections for robotic applications such as sensors, data, network and bus technology as well as control and motor cables. In addition to a large stock availability of robotic cables and assemblies, HELUKABEL also makes customer-specific solutions possible.

Our ROBOFLEX® brand of torsion-resistant control, data, motor and sensor cables offer the right solution for various applications. These cables can withstand chemical, thermal and mechanical stresses associated with torsion, bending, flexibility, abrasion, and are resistant to notches, oil and weld spatter.

In addition to our ROBOFLEX® brand of cables, our HELUROBOTICS® portfolio also includes the capabilities to design and manufacture complete robotic dress pack systems that protect and guide your unique fill package from the constant 3D motion of the robot as well as the environmental hazards of the specific application.

We are happy to help you select the right products for your specific application and are available to answer any questions you may have.

Call us at 847-930-5118 or send us an email!

Featured Products

HELUDATA® ROBOFLEX®-D PUR UL/CSA

PUR robot data cable

UL (AWM) 300V

+90°C

D-shield, EMC-preferred type

Torsion load/cycles: 5 Mio. at +/- 180°/m

Bending cycles: 5 Mio.

Variant: HELUDATA® ROBOFLEX® PUR UL/CSA (Non-shielded)

HELUDATA® ROBOFLEX®-PAIR-D PUR UL/CSA

PUR twisted pair robot data cable

UL (AWM) 300V

+90°C

D-shield, EMC-preferred type

Torsion load/cycles: 5 Mio. at +/- 180°/m

Bending cycles: 5 Mio.

HELUCONTROL® ROBOFLEX®-D PUR UL/CSA

PUR robot control cable

UL (AWM) 600V

+90°C

D-shield, EMC-preferred type

Torsion load/cycles: 5 Mio. at +/- 180°/m

Bending cycles: 5 Mio.

Variant: HELUCONTROL® ROBOFLEX® PUR UL/CSA (Non-shielded)

HELUPOWER® ROBOFLEX®-D PUR UL/CSA

PUR robot motor cable

UL (AWM) 1000V

+90°C

D-shield, EMC-preferred type

Torsion load/cycles: 5 Mio. at +/- 180°/m

Bending cycles: 5 Mio.

Variant: HELUPOWER® ROBOFLEX® PUR UL/CSA (Non-shielded)

HELUPOWER® ROBOFLEX® HYBRID-D PUR UL/CSA

PUR robot power & signal hybrid cable

UL (AWM) 1000 V

+90°C

D-shield, EMC-preferred type

Torsion load/cycles: 5 Mio. at +/- 180°/m

Bending cycles: 5 Mio.

Variant: HELUPOWER® ROBOFLEX® HYBRID PUR UL/CSA (Non-shielded)

HELUDATA® ROBOFLEX®-recycle PUR UL/CSA

PUR robot sensor cable

UL (AWM) 300V

+105°C

Torsion load/cycles: up to 10 Mio. at 360°/m

Bending cycles: up to 10 Mio.

HELUKAT® PROFINET Type R

Product Info

PROFIBUS L2 Torsion

Spec Info